Multilevel Groundwater Sampling for Former Manufacturing Site

Abstract

GEL, working with URS were given the task of developing a cost effective means to isolate and reliably sample groundwater quality and head data from several distinct vertical zones within a complex geological environment.

Equipment Used

The Solinst 7-Channel CMT (Continuous Multichannel Tubing) Multilevel System

Background

Geotechnical Engineering Ltd (GEL) is an experienced drilling company operating in the United Kingdom. GEL, working with URS were given the task of developing a cost effective means to isolate and reliably sample groundwater quality and head data from several distinct vertical zones within a complex geological environment. The investigation took place at a former manufacturing site in South Wales before it was sold to a new company.

The project‚??s scope was largely driven by environmental contamination. Traditional groundwater monitoring approaches were considered. Clustered wells would have proved to be too expensive whilst nested wells would have proven too unreliable.

The Solution

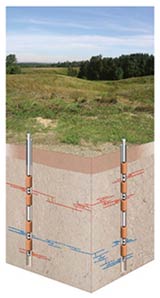

GEL selected the Solinst 7-Channel CMT (Continuous Multichannel Tubing) as the most suitable option, installing a total of 3 Systems to between 6 and 8m below ground level. Five to seven screened zones were monitored in each of the 3 multilevel systems. These screened ports were surrounded by approximately 0.3 m of pea gravel with layers of bentonite pellets above and below each port to isolate the sampled zones.

GEL selected the Solinst 7-Channel CMT (Continuous Multichannel Tubing) as the most suitable option, installing a total of 3 Systems to between 6 and 8m below ground level. Five to seven screened zones were monitored in each of the 3 multilevel systems. These screened ports were surrounded by approximately 0.3 m of pea gravel with layers of bentonite pellets above and below each port to isolate the sampled zones.

GEL staff were trained by RSH personnel and were then able to construct a seven port CMT system within an hour. It should be stated that nested or clustered wells would have taken 2-4 times longer and therefore the CMT system saved Geotechnical a significant amount of time and money. The total time for drilling and installing each 8m well was less than 90mins but does vary according to geology.

Original site investigations from dedicated monitoring locations suggested possible leakage of hydrocarbons from the waste recycling centre. However, the CMT multilevel systems were installed near the periphery of the site and initial testing has suggested that there is no transgression of hydrocarbons offsite.

CMT multilevel systems do allow for a more detailed characterisation of groundwater dynamics.

Groundwater Sampling Options

Groundwater sample collection using the CMT or Waterloo Multilevel Systems, must be conducted with devices that can extract water or samples from either 1/2‚??ID (12mm), 3/8‚??ID (10mm) or 1/4‚??ID (6mm) depending on the number of zones being monitored. There are a number of options for obtaining groundwater samples from these systems which include:

- Peristaltic Pumps ‚?? These are ideal for applications where the water level is within an estimated 25ft (7.6m) of ground surface. The Peristaltic Pump is most often used with 6mm (1/4‚??) LDPE tubing that is lowered into the channel of the CMT.

- Mini Inertial Pumps are used up to 50m below ground surface, where the water level is too deep for peristaltic pumps. Inertial pumps basically consist of a long length of polyethylene tubing with a check valve placed at its base. By lowering and raising the tubing typically by hand (usually1ft), a pulse or slug of groundwater migrates up the tubing and can be collected at the surface. For depths up to 15m, Low Density Polyethylene (LDPE) is used or where depths approach 50m, PTFE/FEP is used. friction effects encountered at greater depth. The mini inertial pump will allow flow rates up to 150-200ml/min.

- Micro Double Valve Pumps ‚?? Standard double valve pumps (5/8‚?? or 16mm diameter) or the bladder pump (1‚?? or 24mm) are too big for CMT systems but are suitable for larger monitoring wells. The micro double valve pump has been designed for the CMT multilevel system to cope with depths greater than 30m. The mDVP is also suitable for VOC sampling as inertial and peristaltic pumps are not considered appropriate. The Micro DVP is a viable sampling option that is capable of pumping at rates of 150 ml/min when placed within the narrow CMT channel. A manifold at surface connects the pump to a drive gas (compressed air/N2 source), and the pump is controlled using the 466 Solinst Electronic Control Unit.

- Vapour Sampling in the CMT. The CMT System is also ideal for gas vapour sampling. The CMT System is constructed with ports and plugs to seal channels exactly as in a groundwater sampling application. The only additional component is another plug placed at surface to seal the top of the sampling channel. This upper plug has a push fit connection that is used with 1/4‚?? (6mm) tubing to enable a gas sample to be drawn from the CMT port to surface using a Hand Vacuum pump or Peristaltic Pump.